Slab Selection Process

01 – Research Stone Types

Read up on the different types of stone and maintenance required. In general, granite, quartzite, engineered stone, porcelain and soapstone are recommended for daily kitchen use. Marble, limestone travertine, onyx and slate are softer stones that are recommended for low acid-wear areas.

02 – Review Our Website

Visit our website to look through our products and see which slabs fit your vision. After you have reviewed a few selections online, come to our slab gallery. You may call ahead to make sure specific colours are exposed for viewing.

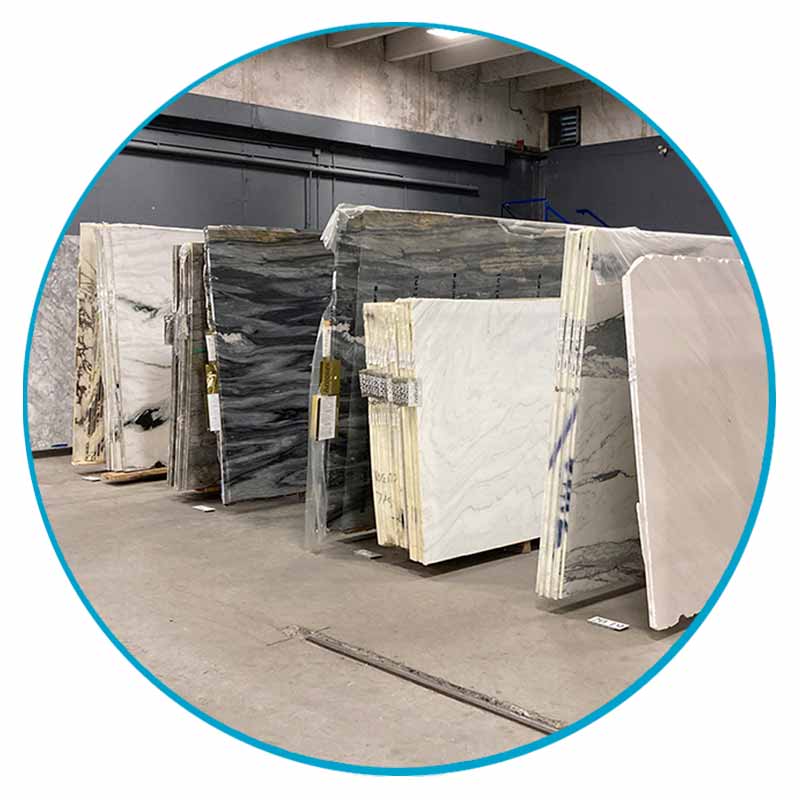

03 – Visit Our Slab Gallery

Be prepared to spend some time! If possible, bring other interior design samples to coordinate with our products, such as paint chips, cabinet and tile samples.

04 – Photograph your choices

Take pictures of your stone choices and barcodes. When you are ready to finalize your selection, the barcode (or SKU) will identify the stone name and block number for your fabricator. Slabs within the same block are similar in appearance so the piece you see displayed will be representative of the slabs behind. Your fabricator will provide you with the installed price (including material, transport, templating, fabrication and installation) and will purchase the material on your behalf.

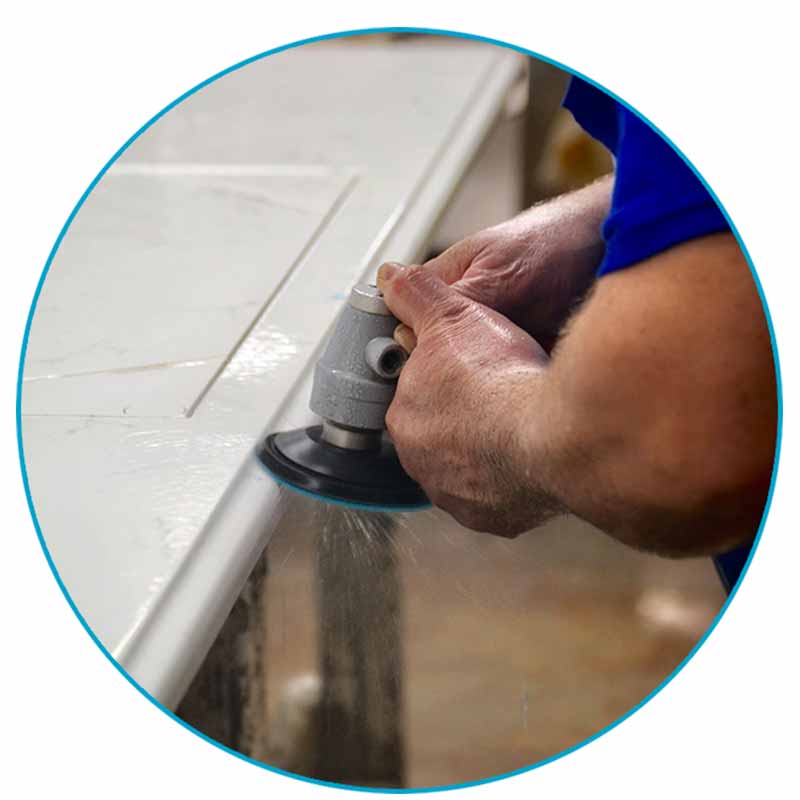

05 – Fabrication

Once you have provided your stone fabricator with a deposit on the project, they can issue us a purchase order. Your fabricator will request the required amount of slabs within your selected block of stone, based on size and condition, and will guide you through the fabrication process.